How We Make Ice Cream

Ben & Jerry's is known for our delicious flavors, but did you know everything that goes into how we make ice cream?

Ben & Jerry's is known for our delicious flavors, but did you know everything that goes into how we make ice cream?

It all starts, of course, with the cow.

In Canada, our milk and cream comes from Canadian dairy farms, and is shipped to our Simcoe, Ontario factory.

In the United States, our milk comes from tens of thousands of cows, from the hundreds of local farms that sell their raw milk to the St. Albans Cooperative Creamery in St. Albans, Vermont. At the Co-op , the milk is separated into heavy cream and condensed skim milk, then shipped by tanker truck to our St. Albans and Waterbury Vermont factories. Learn more about Caring Dairy!

Content and/or functionality on this page requires you to accept cookies.

When the trucks arrive at the factory, the milk and cream are pumped into four 6,000-gallon storage silos, and kept cool at 36 degrees until we’re ready to convert them into Ben & Jerry’s ice cream.

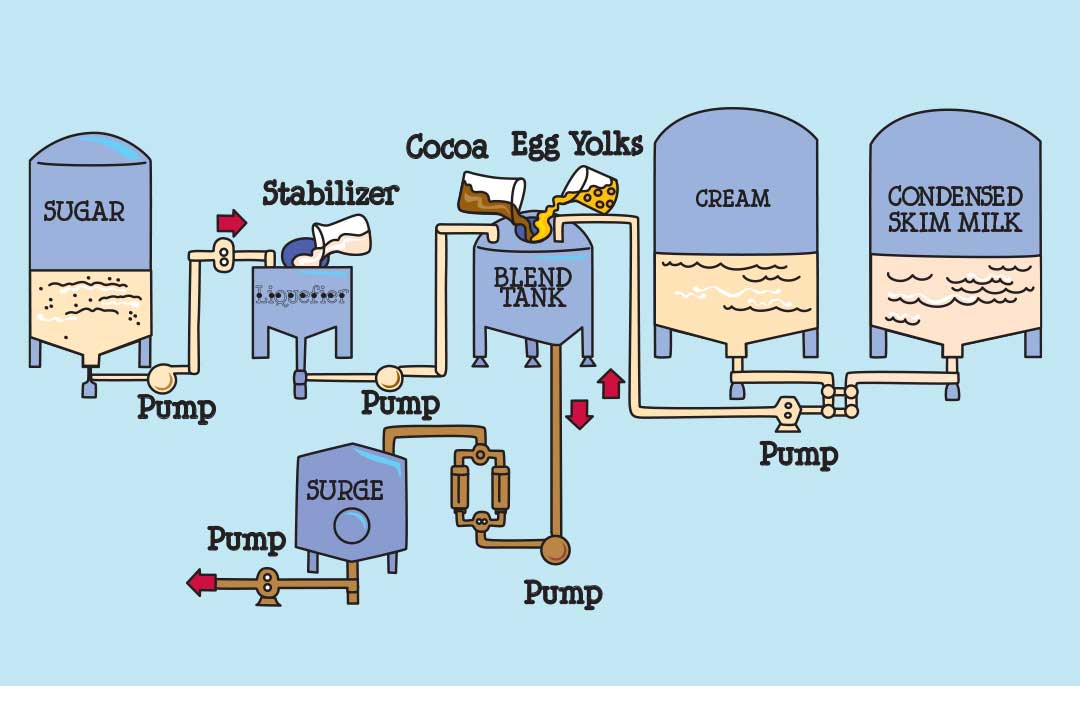

In the overall ice cream production scheme of things, making the mix – and making it most excellent – is perhaps the most important part of the whole process. A very skilled and experienced person known as the Mix Master performs mix-making procedures at the Blend Tank, our 1000-gallon stainless steel mega-blender.

A batch of ice cream mix starts with heavy cream, condensed skim milk, and liquid cane sugar. To these ingredients the Mix Master also adds egg yolks, cocoa powder for our chocolate flavors, and natural stabilizers which help prevent heat shock and formation of ice crystals.

All of the ingredients are blenderized for 6 to 8 minutes, resulting in either a white "sweet cream" mix, or a chocolate mix.

The completed batch of mix is then transferred through one of two strainers into the Surge Tank. The Surge Tank is where the mix is stored until it is ready to begin the pasteurization process.

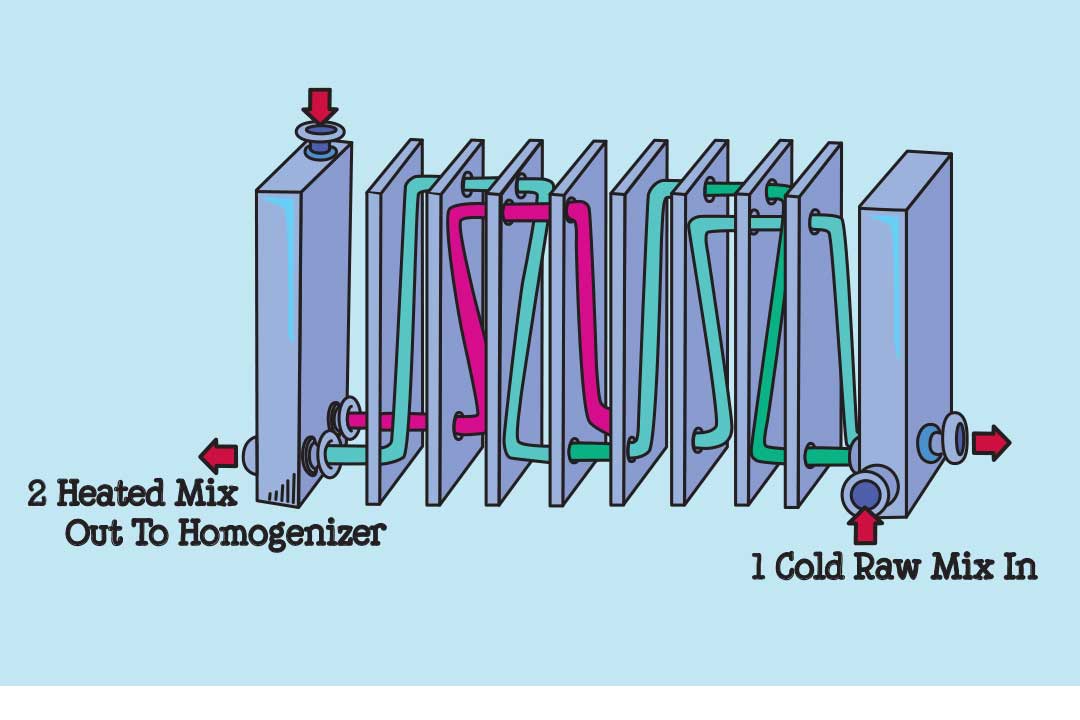

After the ice cream mix is blended, it’s ready to be pasteurized and homogenized. Pasteurization is the process of heating the mix in order to kill harmful bacteria. The Pasteurizer is made up of a series of very thin stainless steel plates. Hot water (182 degrees) flows on one side of the plates, and as cold mix (36 degrees) is pumped through on the other side of the plates, heat from the hot water is transferred to the mix, heating it to 180 degrees.

Before the mix has a chance to cool down, it enters the Homogenizer. There, the mix is forced under high pressure (about 2000 lbs. per square inch) through a very small opening so that the fat particles from the cream are so finely divided and emulsified that they do not separate from the rest of the mix. The Homogenizer works like a piston pump: mix is drawn into the cylinder on the downstroke, and on the upstroke, it's forced out at a very high pressure.

The cooled mix is then pumped over to the Tank Room (a 36-degree room with six 5000-gallon mix storage tanks), where it’s held for 4 to 8 hours to allow the ingredients to intermingle (it's kinda like simmering a sauce or allowing a fine wine to breathe - we just don't want to rush it!).

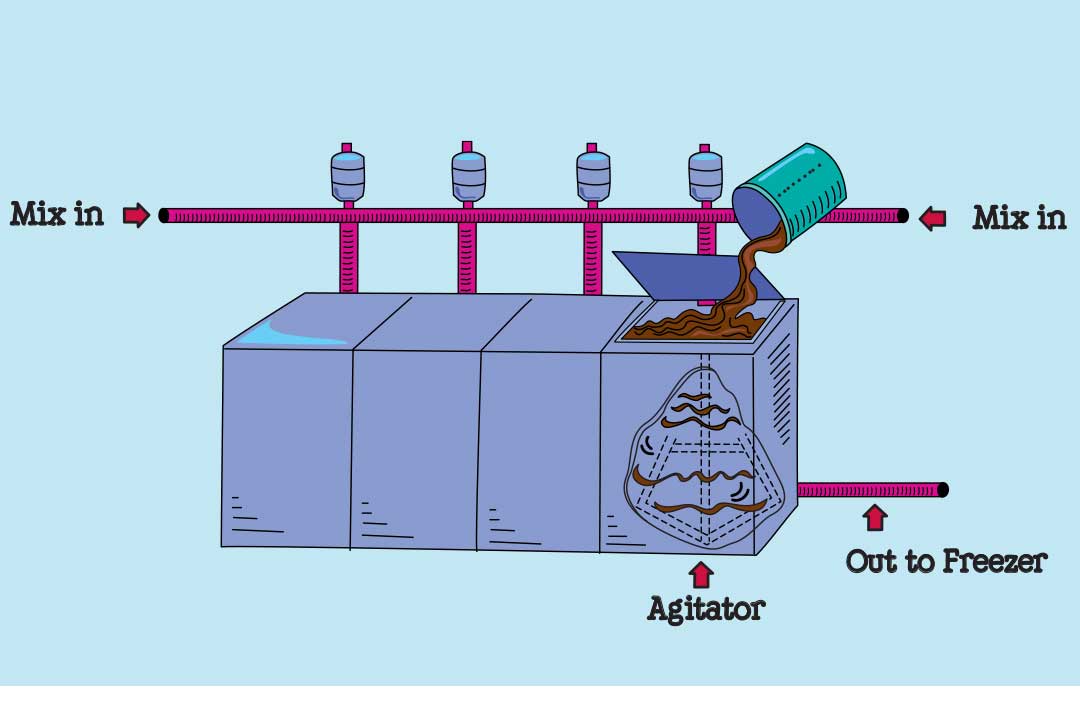

One of the reasons Ben & Jerry's ice cream is so good can be explained with one word: flavor. We take our flavors – and our flavoring techniques – very seriously. The folks who work the Flavor Vats are experts in the fine art of flavoring, and only the finest of flavoring ingredients ever get to commingle with a flavor vat-full of our ice cream mix.

Once the mix has “simmered,” it’s pumped from the Tank Room to the Flavor Vats: a series of stainless steel vats that each hold 500 gallons of mix. It's here that the mix is transformed from basically unflavored to euphorically flavorful, as we add an incredible range of flavorings, purees & extracts, like vanilla, pure peppermint, fruit extracts, banana puree, and even a few liqueurs from time to time.

Once the proper amount of flavoring is added, the mix is pumped to the Freezer. The freezers at our Waterbury plant use liquid ammonia as a freezing agent (40 degrees below zero), and can freeze over 700 gallons of mix per hour.

Here’s how it works: the mix is pumped through a long, freezing cold cylinder known as the barrel. As the mix freezes to the wall of the barrel it is scraped away by revolving blades. When it gets to the front of the barrel it’s no longer mix – it’s ice cream!

The mix enters the freezer at 36 degrees and exits at 22 degrees, which is the same temperature and consistency as a soft-serve ice cream, or as it's called in Vermont, a “creemee.”

After freezing the mix to a nice and creamy 22 degrees, we have a choice: if we’re just making chunkless flavors, like Vanilla or Chocolate, the ice cream is pumped directly to the pint-filling machinery, but if we’re making chunky flavors, the ice cream takes a turn through the Chunk Feeder.

Back in the days before Ben & Jerry’s, the only thing ice cream manufacturers ever put into their ice cream was fruit. That’s why the machine that “feeds” chunks into our ice cream is actually called a “Fruit Feeder.” But considering how many chunky things we have to feed the feeder with, from gobs of chocolate chip cookie dough to fudgy brownies, to cookies and candies and nuts and everything in between…in addition to fruit…we affectionately renamed it!

Quite simply, the Chunk Feeder “feeds” chunks into the ice cream stream. Chunks are top-loaded into the Chunk Feeder hopper, at the bottom of which an auger regulates a steady chunk-flow into a star-wheel. As the star-wheel turns, it pushes the chunks into the stream of frozen ice cream flowing through the feeder. The be-chunked ice cream finally passes through a special blender attachment, which mixes the chunks throughout the stream of ice cream, ensuring an even ”chunk dispersal”.

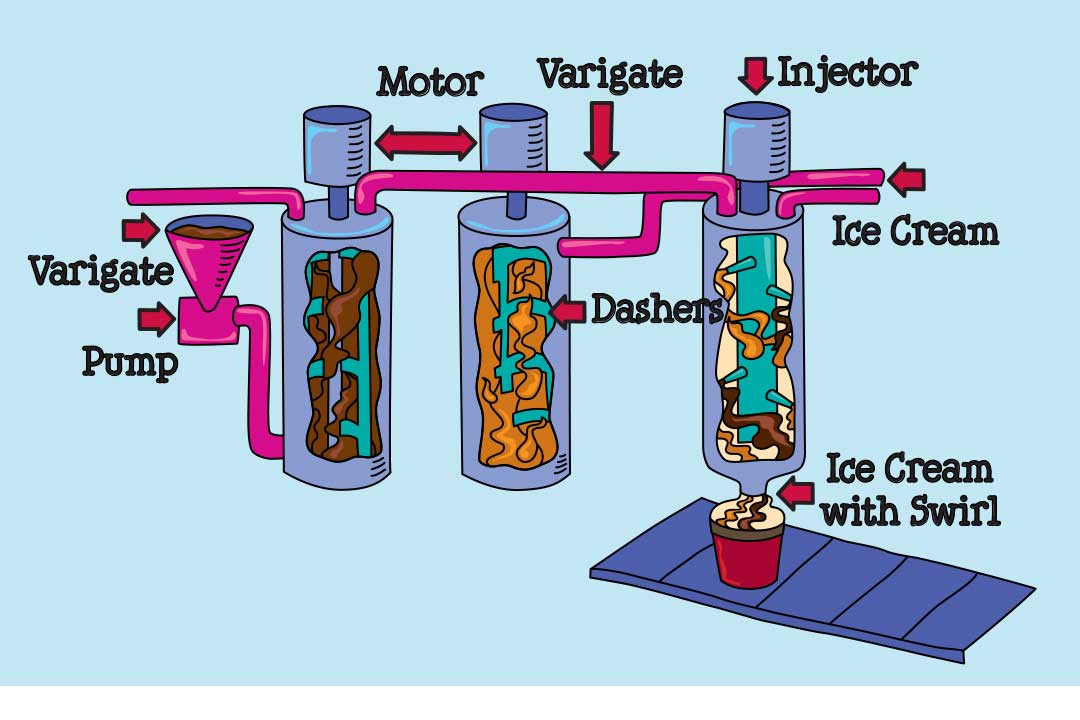

Did you ever wonder how we get those thick, rich swirls of stuff so neatly swirled all through a pint of ice cream? The fancy word for "swirl" is "variegate," and whether it’s fudge, caramel, peanut butter, marshmallow, or fruit, we always use the finest & fanciest variegates we can find. But those great variegates would never find their way into a pint of our ice cream if it weren’t for a great variegate-guidance system.

Luckily we just happen to have the greatest variegate-guidance system there is!

Here’s how it works:

• Variegates must first pass through the Contherm, which lowers their temperature just enough to prevent them from pooling (which is not a good thing).

• Properly cooled variegates pass through the Variegator, which essentially injects them into the ice cream stream (which is a really good thing when it works right, and a really messy thing when it doesn't).

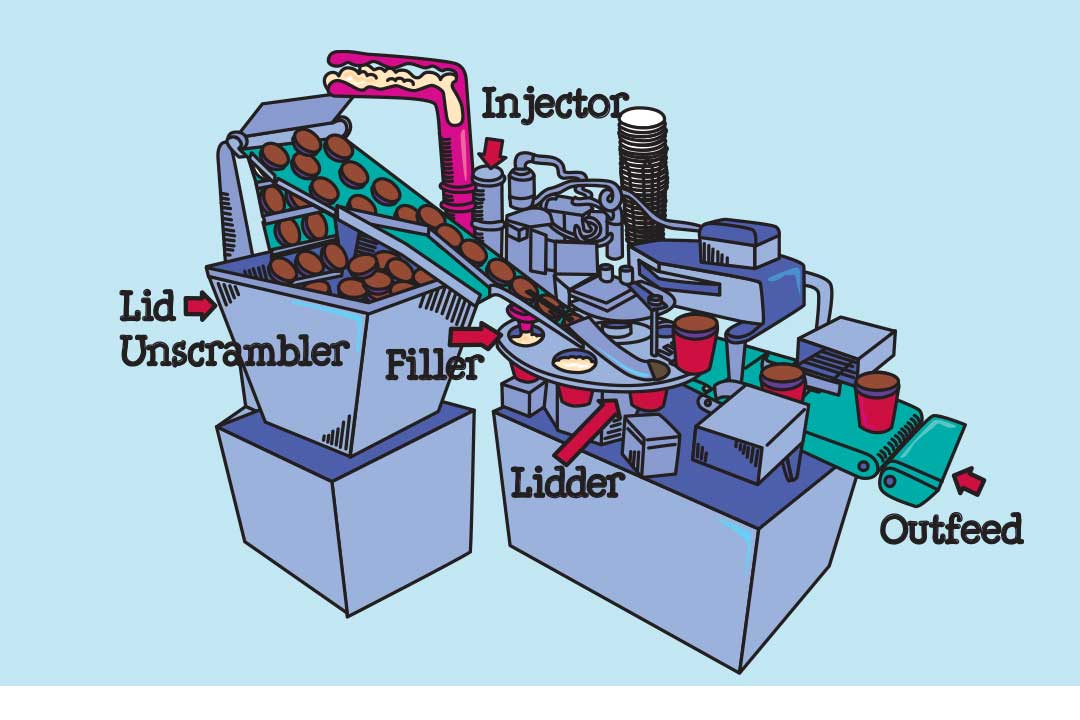

After the chunks and the swirls are added, the ice cream’s ready for dispensing into pint containers. This is done with a most amazing piece of machinery called the Automatic Filler.

Not only does the Automatic Filler fill about 120 pints a minute, but it also performs pre-filling tasks, like dropping pint-cups two-by-two into perfect position so the filler-head can fill them.

In addition, after the cups are filled, the filler further facilitates them towards the lidder, which properly positions & pushes pint lids snugly on the cups.

Finally, a nifty pint-cup lifter frees the pints from the lidder, where a little lever waits to push them out and away on a conveyor belt to the next step in the process.

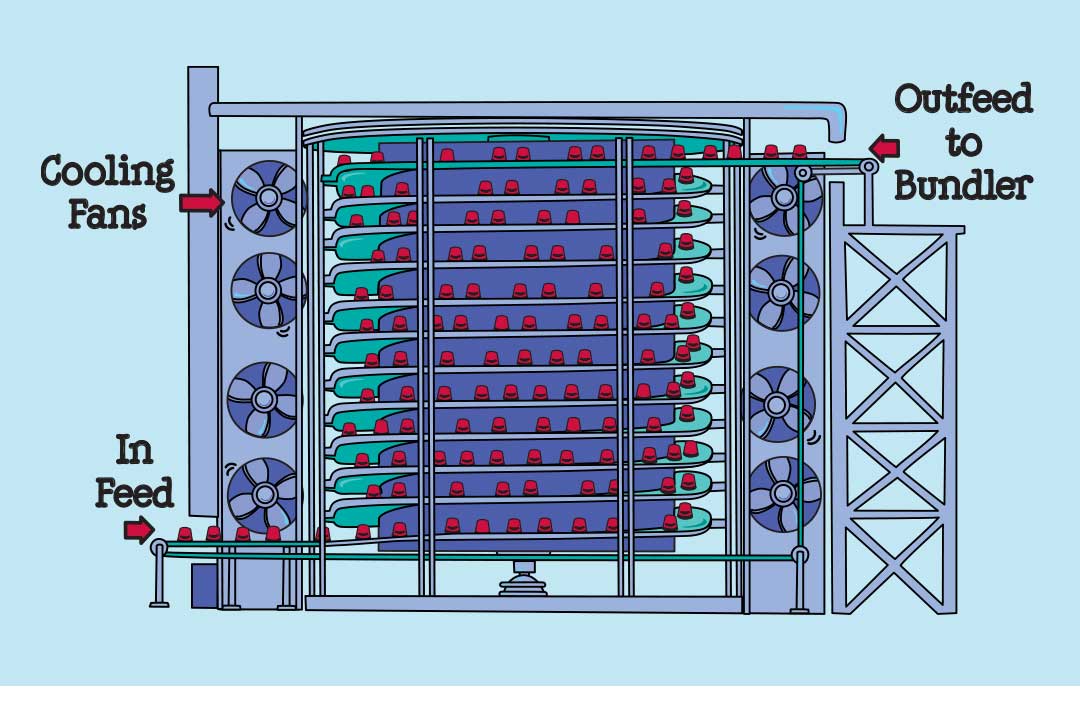

Before the packaged ice cream can be stored or shipped, it needs to be frozen further – from its semi-frozen temperature of 22 degrees above zero, to a fully-frozen-solid state of at least 10 degrees below zero. The process is called “hardening,” and it happens in the Spiral Hardener.

The pints travel by conveyor out of our production room and into the Spiral Hardening Tunnel, a two story, corkscrew-shaped mega-conveyor that’s quite literally the coolest thing in the whole factory.

The actual temperature in the Spiral Hardening Tunnel is 30 degrees below zero, but huge fans blowing in the tunnel create a wind-chill temperature measuring 60 degrees below zero. In this totally polar environment, the pints travel up the slowly spiraling conveyor for three hours, and when they reach the top, their temperature has dropped from 22 degrees above zero (soft-serve consistency) to 10 degrees below zero (fully-frozen-solid consistency!)

Content and/or functionality on this page requires you to accept cookies.

After the pints are frozen solid we wrap them for shipment. First, an invertor flips every other pint upside down, and a freezer worker ensures that 8 pints (2 parallel rows of 4 pints, with every other pint inverted) are properly assembled to enter the Bundler. The Bundler is a heat-tunnel which shrink-wraps plastic around the bundle of 8 pints. The bundled 8-pack is called a “sleeve,” and each sleeve equals a gallon of ice cream. Freezer workers stack the sleeves on shipping pallets which are then stored in our 20-below-zero warehouse to await shipment.

Meanwhile, back in the Quality Assurance Lab, our QA folks are absolute fanatics when it comes to ensuring every flavor of Ben & Jerry's ice cream meets our strict standards of product excellence.

Every thumbs-up they bestow on a Ben & Jerry’s production run gives our ice cream traffic controllers the critical clearances they need to speed Ben & Jerry’s products to their final destinations everywhere….

Our definition of "everywhere" keeps growing more and more everywhere every year!

Ben & Jerry's products are distributed nationwide and around-the-globe in supermarkets, grocery stores, convenience stores, restaurants, cinemas and other ice-cream-friendly venues. And when it comes to ice-cream-friendly venues, of course, we think Ben & Jerry's scoop shops are by far the ice-cream-friendliest!

Content and/or functionality on this page requires you to accept cookies.